Starting a Career in CNC Programming

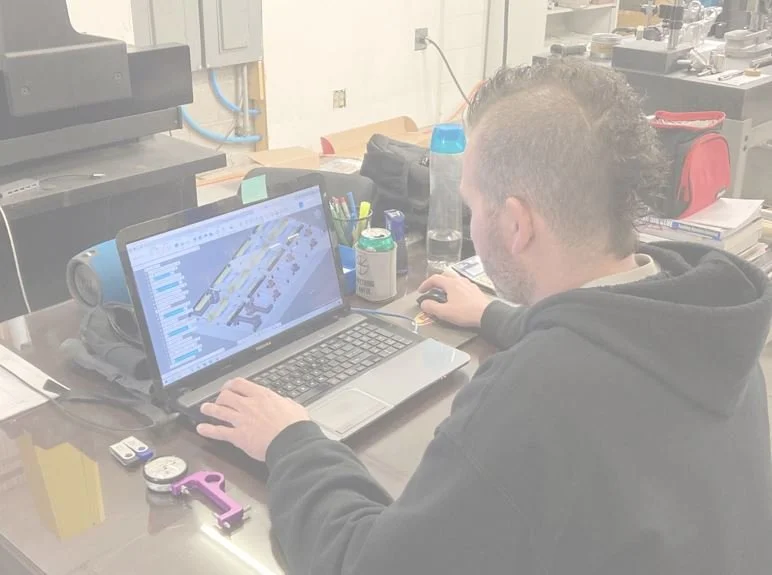

I recently had an opportunity to interview Phil Brown and Umair Riyas from NexGenCAM about how to begin a career in computer-aided manufacturing or CAM. They are applications engineers that specialize in CAM software. Phil and Umair have extensive backgrounds in CNC and CAM/CAD, they offer a few tips to others who may be interested in starting a career in the field.

What mindset is needed to succeed in CAM Programming?

To be successful in CAM you should excel at working in a team environment and be able to accept constructive criticism at times. Being dependable is also a key contributor to being successful as a CNC programmer. To be dependable means showing up on time every day for your job. Typically, CNC programmers are tinkerers and like the challenges that that brings. They like to figure things out with a mechanical aptitude. Being a perfectionist when it comes to their work is also a trait that is ideal for CNC programmers.

What are the skills needed?

Having above average math skills can help in various technical situations. You may use trigonometry functions for troubleshooting and analysis. You may also use math to calculate speeds and feeds of cutting tools. Having a solid set of computer skills and time management skills are essential to being a great CNC programmer. Having the ability to manage stressful situations and learn how to let go of stress as it relates to your career would also be a skill needed for a CNC programmer position.

How familiar with CNC must a person be to get started in CAM?

If the new programmer has a desire to learn and can envision the big picture, they will excel in CNC programming. It can be possible to teach a person who is new to the field how to perform basic CNC programming in a couple lessons. Phil recommends learning Fusion 360 software to anybody getting started in CNC programming.

Learning more about CNC and CAM programming:

To learn more about CAM programming, there are three paths to go down and they are dependent on your needs as a programmer. To learn more about programming you could watch videos about the chosen programming software. There are tutorials that cover many software packages, and they may reduce how overwhelming the learning curve might be.

Another way to learn CAM programming is by taking a guided class which is more specific in the training versus an online video. The benefit with a guided class would be you may be able to program your own parts in the class. This path is more directed to the needs of the programmer than watching tutorial videos.

The third way to learn CAM is by enrolling in customized training from a software company such as NexGen CAM. With this approach, the programmer would be learning the software from industry experts. The training would be tailored to the needs of the company.

To learn more, visit their website at www.nexgencam.com. To see the training classes that NexGenCAM has to offer, follow this link for more information.