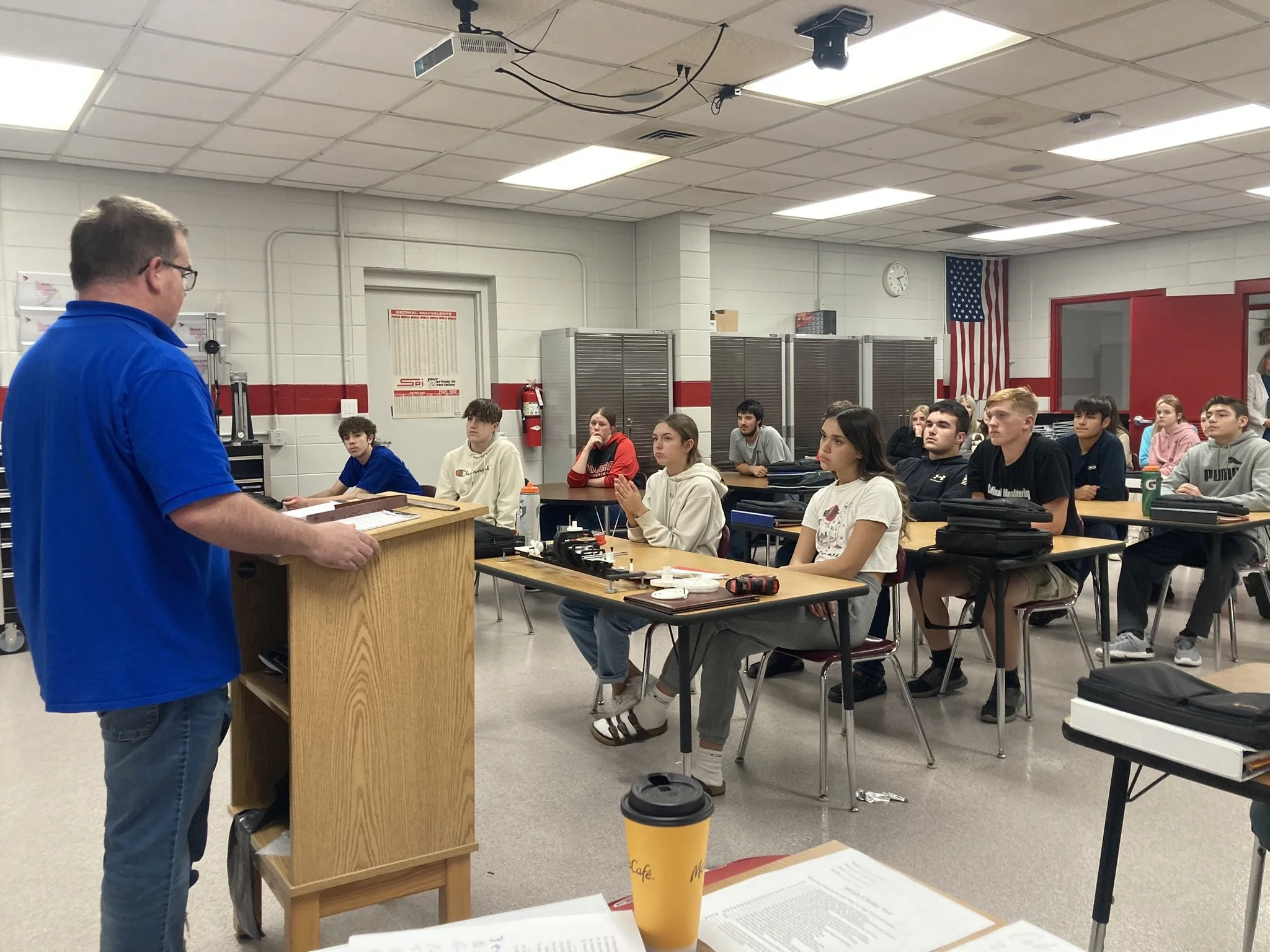

Giving A Technical Education Class Presentation

I was provided with a few opportunities to talk about my STEM project and my career in several schools. It can be a very rewarding experience to a part of. I never saw myself as a speaker or presenter but with my deep knowledge in the subject, I developed a passion for sharing my experiences in manufacturing.

For me, my subject was my career path and how I got started working in manufacturing. I started by making a slideshow for the presentation and showing the students what an apprenticeship program is, and how there are many career paths that an apprenticeship is offered in. I also showed the students that throughout the country there are different economic situations to consider, and I use an example of when I was offered a job in Denver as a Die Manufacturer for the US Mint. Once I applied for the position, I discovered that there was a huge cost of living difference from living in Wisconsin to Colorado. Ultimately, I had to decline the job offer due to the cost-of-living difference and how the position didn’t address it.

I then showed the students how I spent decades working as a machinist, CNC programmer, and journeyman tool and die maker. These experiences led to me being offered a position as a Manufacuring Engineer at a global manufacturing company. Every job that I held was a building block to something greater.

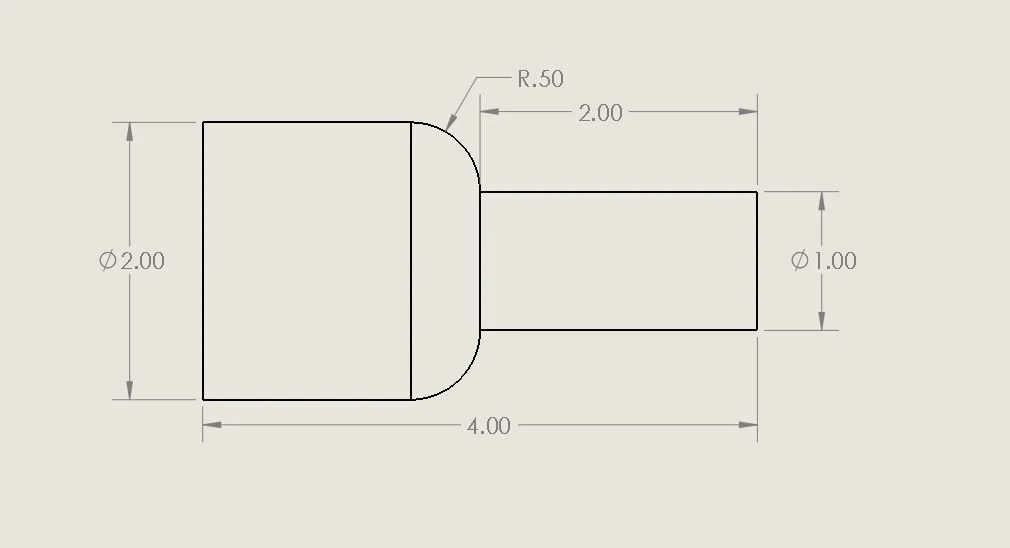

To inspire the students even more, I displayed my 3D printed mechanical clock that I made. I have invested over 2,000 hours in the project and it shows. The clock was made to show students how a mechanical watch works, as the gears are laid out in-line to show each gears function.